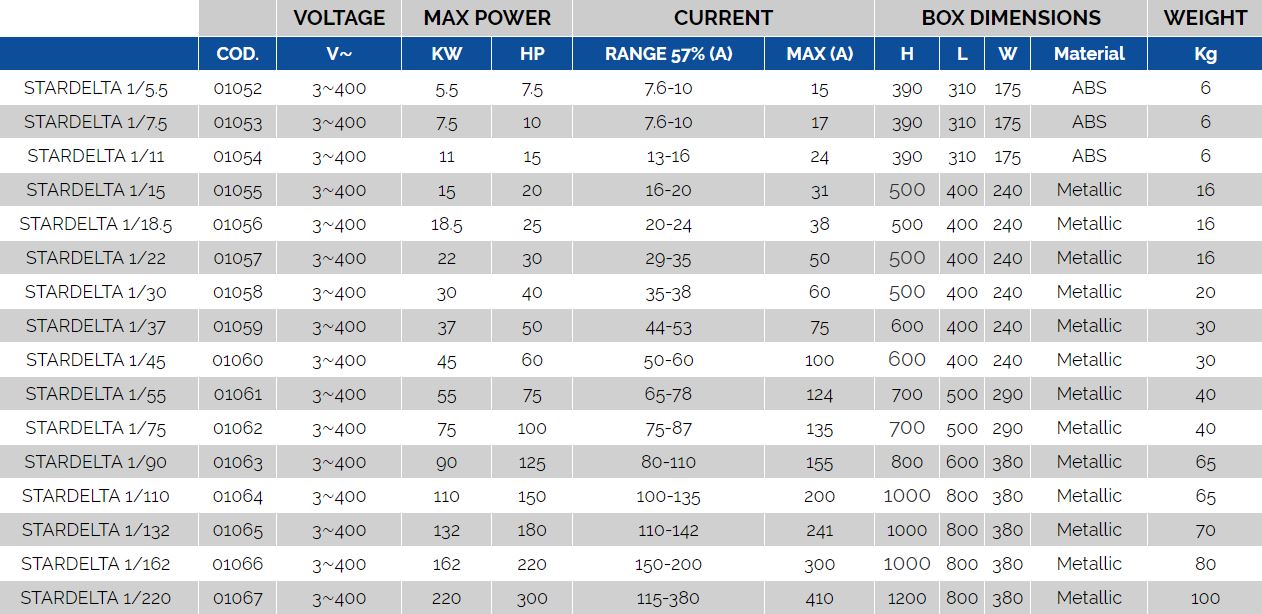

Each star delta control panel has power on, thermal relay tripped and motor running indicator lights, a manual or automatic circuit-breaker, and a master switch with door interlock system. A terminal board allows connection to the users and to external control devices such as pressure switches, float switches, etc.

STARDELTA 1 panels with star-delta starting for an electric pump: star-delta starting is the best known and perhaps the most widely used low voltage starting method.

It is used to start the pump motor with lower levels of mechanical stress and with current limitation during start-up; it does this with the aid of a timed system which switches the control contactors installed inside the switchboard.

Star-delta starting reduces starting current and torque to values of 33% (1/3) of those measured during direct starting.

During start-up, the currents flowing through components are lower than the motor's rated current.

They are suitable for starting centrifugal pumps or pressure booster systems with surface pumps.

Star phase

During this starting phase, the motor windings are connected by a star connection. This is the acceleration phase, and must last long enough for the operating speed to be almost reached.

Switching phase

This is the phase in which the specific contactors are opened and closed to switch from star to delta connection. The duration and calibration of the switching phase are important. Switching is regulated by timers.

Delta phase

Switching is followed by the final phase in the starting process. The motor operates at normal speed and the stator windings, with delta connection, are subjected to the full mains voltage V; the motor torque rises to the rated value.

Motor thermal protection

The motor protection relay is connected to the section of the winding downstream of the main contactor. The current for regulation therefore corresponds to 1/√ 3=0.58 of the motor's rated current.