South Wales (Yuasa Batteries) - Case Study

| Client: | Yuasa Batteries |

| Location: | South Wales, UK |

| Product: | BoreSaver Ultra C, Liquid Enhancer |

| Project Description: | Rehabilitation of wells from iron oxide contamination. |

| Keywords: | BoreSaver Ultra C, well rehabilitation, iron oxide contaminate, IRB biofilm. |

"Specific capacity is back up to 32cm3 an hour with corresponding reduction in operational problems."

Yuasa Batteries is the world leader in the design and manufacture of batteries. Their plant in Ebbw Vale, South Wales produces over 500,000 batteries a year and employs around 350 people. The plant has two boreholes which supply drinking water for the staff and dionised water in their batteries as well as the plant’s showers and fire mains.

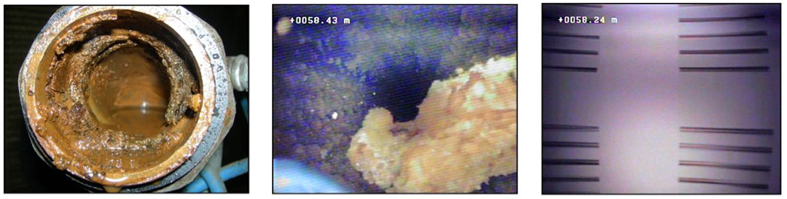

The two boreholes are 75m and 90m deep respectively and were drilled ten years ago. The plant is situated in a heavy ironstone area and in 2007 iron oxide contamination was starting to cause operational problems and a significant reduction in the specific capacity, down from 32cm³ an hour to 15cm³.

We recommended treating the system with BoreSaver Ultra C to remove the build up of deposits on the screens and pumps. Yuasa have been carrying out annual maintenance for the last five years and use BoreSaver liquid every fortnight to maintain the system. Specific capacity is back up to 32cm³ an hour with a corresponding reduction in operational problems.